Who We Are

About LM3 Technologies

At LM3 Technologies, we specialize in delivering advanced industrial vision systems that combine deep expertise in traditional machine vision with cutting-edge AI. Our team brings a rich foundation in manufacturing automation, AI model development, and systems integration—allowing us to engineer holistic, scalable solutions tailored to real-world production challenges. By unifying rule-based logic, deep learning, optical character recognition, dimensional measurement, and robotics guidance into a single platform, we help our clients achieve smarter, faster, and more reliable inspection. From concept to deployment, we don’t just build systems—we solve problems with purpose-built vision solutions that drive measurable value.

Measure

-

Dimensional verification (length, width, height, depth)

-

Hole diameter and spacing

-

Gap and flush measurement

-

Angle and curvature check

-

Surface area estimation

-

Tolerance comparison

-

Coordinate output for robots

Defect Detection

-

Scratch, dent, and crack detection

-

Surface voids and pitting

-

Discoloration and stains

-

Coating defects (e.g. landslide, bubbling, bead clumping)

-

Weld quality and seam inspection

-

Edge damage or deformation

-

Foreign object detection

Anomaly Detection

-

AI-based pattern deviation

-

Real-time defect classification

-

Detection of new/untrained defects

-

Confidence-based decision making

-

Dynamic inspection zone

-

Self-learning from new samples

-

Defect trend analysis over time

OCR

-

Alphanumeric code reading

-

Part ID and serial number logging

-

Label and date code verification

-

Lot code matching

-

Tolerance for reflective surfaces

-

Automated pass/fail comparison

-

Integration with ERP/MES

Part Presence

-

Component verification pre-assembly

-

Missing part detection

-

Multiple feature confirmation

-

Pre-weld/packaging check

-

Flexible zone detection

-

Verify correct orientation

-

Detect loose or extra parts

Assembly Check

-

Fastener presence & torque witness

-

Label and sticker placement

-

Clip or tab validation

-

Sequential build verification

-

Subassembly completeness

-

Hardware color and location

-

Mixed-part confirmation

Robot Guidance

-

Vision-guided pick and place

-

Part localization in bin or tray

-

3D part pose estimation

-

Automatic coordinate output

-

Offset correction for skew/shift

-

Synchronization with cobots and PLCs

-

Part changeover re-learning

Color Matching

-

Color tone and hue detection

-

Paint uniformity inspection

-

Dye/stain consistency checks

-

Fade and discoloration alerts

-

Material mix detection

-

Edge blending validation

-

Brightness/contrast normalization

On-Prem

Models

CNNs

.png)

Pre

Trained

Data

Storage

QC Hero

AI Vision Model Training Pipeline

QC Hero is our proprietary AI engine built to power next-generation vision inspection with speed, flexibility, and intelligence. Designed for high-performance training and deployment, QC Hero leverages Google Cloud TPUs and scalable model management to enable advanced classification, segmentation, and anomaly detection—empowering manufacturers to solve complex inspection challenges with precision and ease.

PAQi

Modular Industrial Controller & Edge PC

PAQi is our industrial AI vision platform built for real-time inspection, process control, and traceability on the factory floor. With flexible deployment, integrated I/O, and support for multiple cameras and vision models, PAQi simplifies complex inspections while delivering high-speed, high-accuracy results—reducing hardware, improving uptime, and driving smarter automation.

LM3's AI Vision Deployment Platform

LM3’s inspection strategy follows a tiered, cost-conscious process that prioritizes efficiency without compromising performance. We begin with AI-based inspection using QC Hero, the fastest and most cost-effective approach for most applications. If additional accuracy or functionality is needed, we scale into rule-based vision tools, precision optics, or 3D imaging, only when justified. This stepwise methodology ensures clients receive solutions that are technically sound, financially optimized, and fully aligned with production goals—delivering the right technology at the right price.

2D Vision and AI

Traditional Vision

3D and Advanced Optics

Hybrid Intelligent Systems

Our systems are built to scale, whether deployed as a single inspection point or a multi-station network with edge-to-cloud connectivity. LM3’s deployment approach includes PLC integration, robot guidance, MES communication, and traceable data infrastructure, delivering systems that not only inspect but enhance production. With on-site validation, remote support infrastructure, and an adaptive approach to hardware and software, the AI Vision Deployment Hub empowers manufacturers to unlock value at every stage of automation.

Cloud-based quality management and analytics

Enterprise Systems

Cloud Storage

ERP Platform

Compliance Reporting

Line-level coordination and traceability

Factory Floor

SCADA

MES

OPC UA

SQL

REST APIs

Local automation and control components

.png)

Station Systems

.png)

.png)

PLCs

HMIs

Robots

Sensors

Actuators

Conveyors

AI Vision + Local Intelligence

PAQi

Controller

.png)

Edge PC Units

Cameras

Lighting

Inference Server

SQL Database

_H03_2k.png)

SSD Storage

On-Prem

AI Models

Software Suite

Optics Engineering

We evaluate every application's environment, material, and inspection goal to configure the most effective imaging setup—whether it requires 2D, 3D, infrared, or thermal solutions. Our expertise ensures optimal lighting, camera, and lens selection to maximize performance and image quality for accurate defect detection.

2D imaging

3D imaging (stereo, laser, ToF)

IR and thermal imaging

Hyperspectral imaging

Custom lens selection

Optical filtering

Field-of-view planning

Depth calibration

Lighting control

Environmental compensation

Optical enclosures

Cleanroom imaging setups

Integration

We design solutions that bring together diverse technologies—robotics, sensors, PLCs, vision, AI, and automation—into a unified, intelligent system. Whether you're launching a new cell or retrofitting legacy equipment, LM3 ensures seamless integration across hardware, software, and control layers for optimal performance.

Robot integration

Sensor integration

PLC programming

Camera mounting

Electrical panel design

I/O routing

Part presentation systems

Communication protocols

Motion control

Sequence logic

Custom interfaces

Multi-system coordination

Vision Intelligence

Our AI and vision specialists develop inspection strategies using the best tools for the job—AI models, traditional tools, or both. From training deep learning models to managing datasets and optimizing inference pipelines, we help customers deploy smarter, faster inspection across product lines.

Defect data collection

Annotation and labeling

Model selection (CNNs, YOLO, etc.)

QC Hero pipeline integration

Transfer learning

Segmentation and classification

Training and tuning

Hybrid rule-based + AI systems

Inference optimization

Live model updates

Real-time defect feedback

Edge and cloud deployment

PAQi LayerCheck

Layered Assembly Verification

Built for multi-stage or layered assemblies, PAQi LayerCheck uses a single or multi-camera approach with true object detection via QC Hero to confirm part sequencing, fastener presence, and build quality. VBAI and structured lighting systems can be added for detailed depth/position validation.

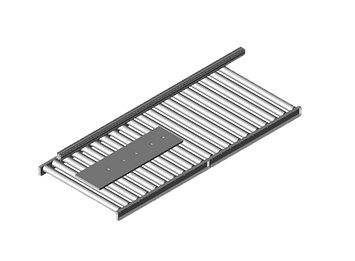

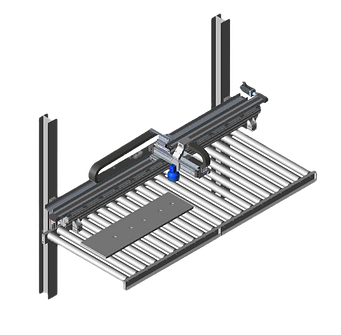

PAQi PaP

Vision -Led Robotic Pick & Place

PAQi PAP enables fast and accurate robotic picking through calibrated vision systems, detecting object presence, orientation, and placement accuracy. Compatible with QC Hero for detection/classification, PhotoNeo and SICK 3D cameras for bin picking, and integrates with robot platforms via PROFINET and EtherNet/IP.

PAQi Measure

Dimensional Inspection

PAQi Measure delivers sub-millimeter accuracy using calibrated vision and lighting systems. It supports metrology tools from SICK, as well as QC Hero’s AI overlay for edge detection and defect-based dimension filtering. Ideal for stamping, machined, or additive-manufactured parts.

PAQi CellView

Autonomous Inspection Cell

A fully enclosed, plug-and-play inspection cell for critical components and part families, PAQi CellView pairs QC Hero AI detection with modular camera and lighting setups. Supports VBAI logic or custom Python-based workflows and integrates with SICK, Keyence, and Basler imaging tools.

.jpg)

PAQi Workbench

Operator-Guided Inspection

Perfect for manual workstations, PAQi Workbench adds real-time AI feedback, part presence verification, and guided assembly checks. Works with QC Hero, VBAI, and SICK Inspector to validate operator-assembled parts and ensures that errors are caught before downstream impact.

PAQi InLine

Production Line Inspection

This solution provides high-speed, non-contact inspection in live production lines. From paint and coating defects to connector pin checks and orientation validation, PAQi In-Line leverages QC Hero for object/defect classification, with support for VBAI, and SICK solutions to fit the task.

PAQi GateKeeper

End-of-Line Quality Assurance

PAQi GateKeeper is the final inspection barrier before packaging or shipment. Optimized for complex assemblies, it combines QC Hero’s multi-object detection with barcode/OCR verification and 3D sensors for full-surface analysis. Integrates with PLCs and MES for pass/fail gating and traceability.

PAQi Moldview

Injection Molding Inspection

Designed for plastic and metal molding applications, PAQi Moldview inspects mold cavities, ejected parts, and tooling with high-resolution vision. Integrates seamlessly with QC Hero AI models, SICK Inspector series, and VBAI for real-time visual checks on flash, short shots, misloads, or deformation.

Deploy Solutions in Production

Every LM3 system—from medical coating inspection to automotive assembly verification—is powered by the same scalable PAQi architecture, giving our customers a unified, future-ready platform for factory automation.

.jpg)